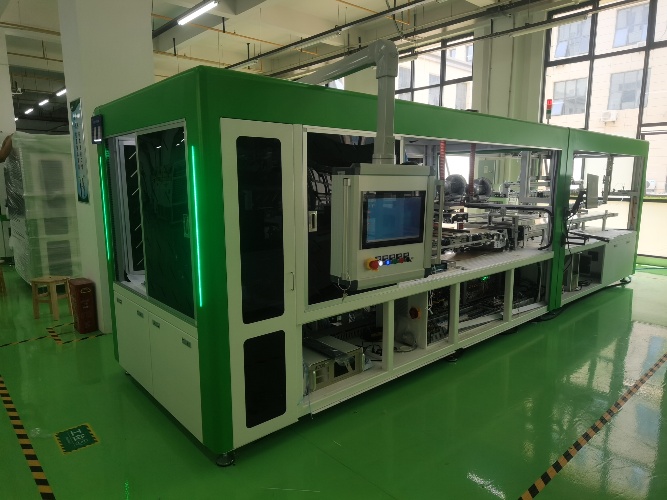

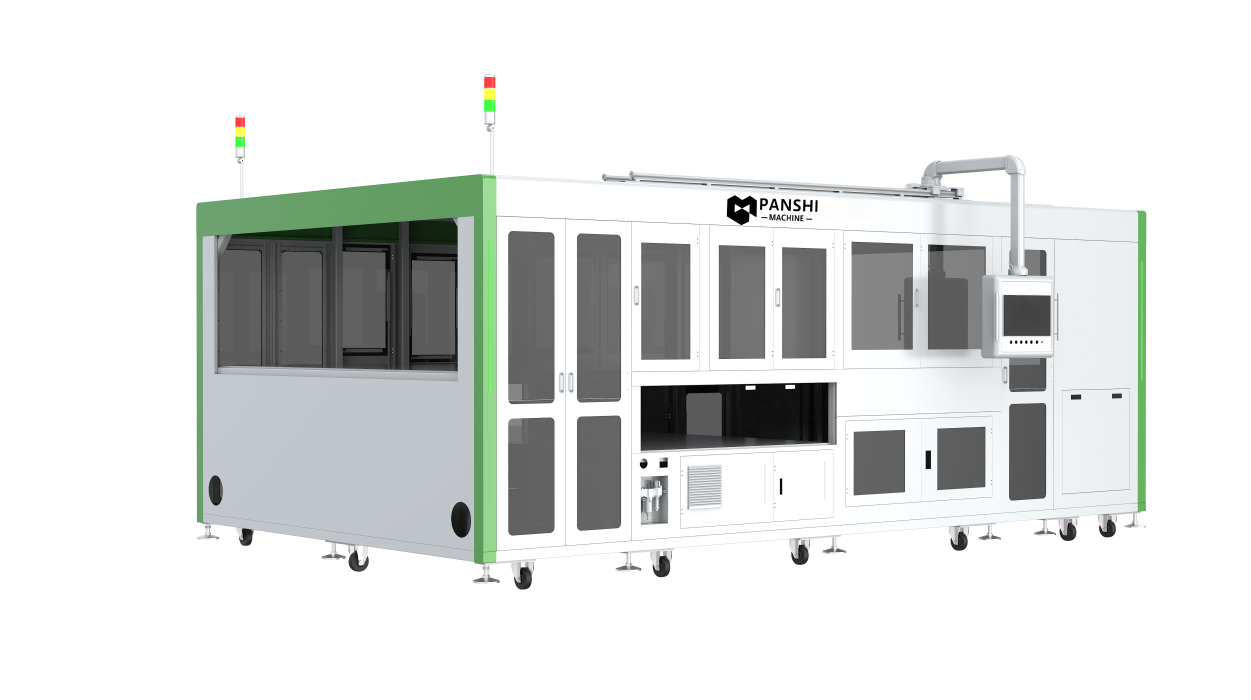

Stringer Machine

Suitable for solar module production line in solar panel factories

Performance Features:

·The equipment is specifically designed for BC solar cell string welding, offering great cost-effectiveness.

·The equipment boasts high stability and reliability, with easy and convenient maintenance.

·With its unique design, it achieves efficient and quick string welding, significantly reducing false welding and white exposure.

·Specially designed to address BC welding distortion, greatly reducing the degree of cell distortion and improving yield.

·Customized designs can be tailored according to customers’ actual production needs to meet their specific customization requirements effectively.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Supply of Customized Solutions

Based on the customer’s factory, we provide tailored production line solutions. While meeting production capacity requirements, we reasonably configure production equipment, balancing reliability and cost-effectiveness.

Supply of Reliable Production Equipment

We have independently developed twelve core equipment models. To date, we have delivered 19 sets of 100MW photovoltaic module production line equipment and various self-developed stand-alone equipment to over 20 countries and regions worldwide.

Supply with Delivery Commitment

In alignment with the customer’s project schedule, we complete order delivery before the mutually agreed delivery date.

Turnkey Solutions Supply

Customized solutions, equipment selection, order delivery, equipment installation, training, and satisfactory after-sales support.